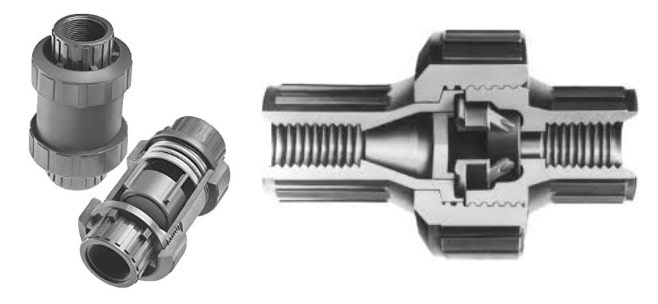

2. Spring Loaded Y Check Valve: ( Types of Check Valves )

The figure 2 shows the typical illustration of spring-loaded Y check valve. Its operation is similar to the in-line check valve but there is only one difference, that is the disc is placed at an angle to the fluid flow direction. This change enables the check valve to inspect and maintain while the valve connected to the pipeline. But, because of its shape, it takes more space than the in-line valve.

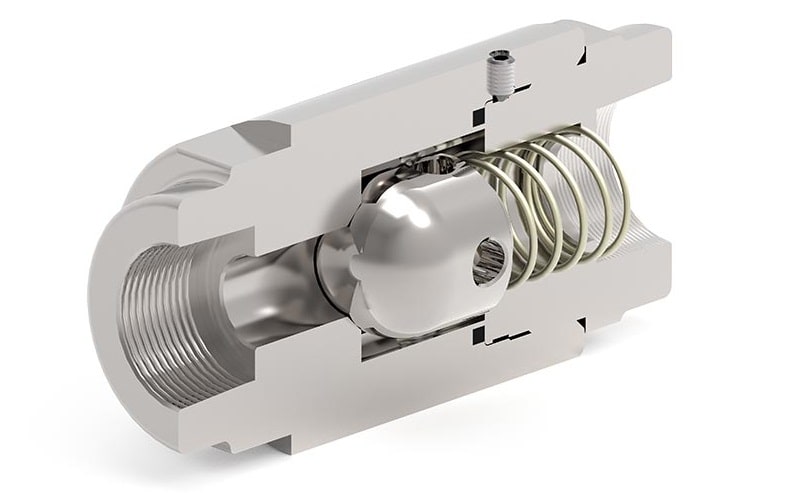

3. Ball Check Valve: ( Types of Check Valves )

The ball check valve either be spring loaded or free-floating type. As the cracking pressure for spring loaded valve is more than that of free-floating ball valve. Thus, the free-floating type is used for low pressure application and the spring-loaded type is used for high pressure application. The figure 3 shows illustrations of spring-loaded ball check valves. Its working principle is also similar to the in-line check valve, but instead of disc, a ball is used for the purpose.

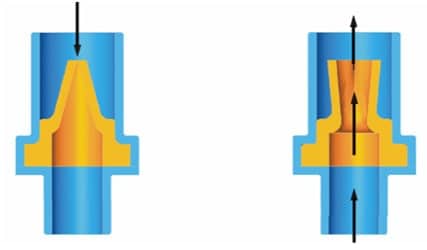

4. Diaphragm Check Valve: ( Types of Check Valves )

It consists of a rubber diaphragm that flexes inside the valve to open or close the passage. The figure 4 shows schematic diagram of a diaphragm check valve. Because of the diaphragm, there is very low or no cracking pressure possessed by the valve. As the pressure at inlet increases the diaphragm flexes more and the size of passage increases accordingly. In case of any backflow, the diaphragm is forced against the opening and seal the passage to prevent backflow. These kind of check valves are ideal for low pressure or vacuum application. ( Types of Diaphragm Valve )

5. Lift Check Valve: ( Types of Check Valves )

It consists of a spring-loaded disc that lifts off when the pressure at inlet exceeds the cracking pressure and allow the fluid to pass through the valve, as shown in figure 5. As, the pressure at inlet decreases less than the cracking pressure or there is any backflow in the system, the disc reverses its movement by the help of spring force and closes the valve opening. Instead of spring, gravity assisted disc movement is also incorporated in the valve sometime.

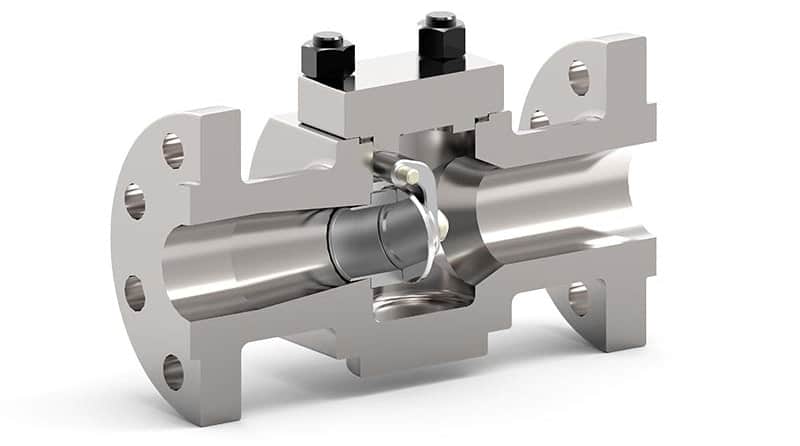

6. Swing Check Valve: ( Types of Check Valves )

This check valve is also known as tilted disc check valve. It consists a disc that is hinged radially on one side. As the pressure at the valve inlet port increases, the disc swings about the hinge and opens the passage for fluid flow. In case of back flow, the disc swings back to initial position and completely closes the passage. There is no spring used in this valve and the movement of the disc is completely relies on the gravity. Figure 6 shows a swing check valve for instance.

7. Duckbill Check Valve: ( Types of Check Valves )

This check valve uses a soft tube that changes its shape according to the flow direction and hence, ensures the unidirectional flow of fluid inside the valve. If fluid is flowing in forward direction, the end of the soft tube changes its shape into diverging type and allowing the fluid to pass easily. As, the fluid reverses its direction, the end of the soft tube becomes converging and restricts the fluid to enter into it, see

HCL METAL

Our Locations

One-Stop Internationl Manufacturing Services