9. Insert Nut: ( Types of Nuts )

An insert nut is referred to as that nut which is found providing a socket that should specifically be fully threaded in order to resolve all the purpose of a wooden work piece, which seems to be quite similar to a wall anchor. Insert nuts are found being inserted at the holes which are found to be pre-drilled one amongst the two means: either screw in or hammer in. In both the cases, the external protrusions is observed biting inside the wood which is directly or indirectly responsible for preventing the nut from either turning or pulling out.

Insert nuts are found having their merits over the other nuts like barrel nuts or T-nuts, as they are the ones which are known to be installed from either of the one side of the work piece.

10. Knurled Nut: ( Types of Nuts )

A knurled nut is referred to as that nut which is knurled outside the surface. This is what is responsible for tightening the nuts by the impact of a bare hand and which can secure the nut into a handle or a cover

Knurled nuts are the ones which are found to be used commonly in any of the application where these fasteners will not be placed permanently, which means they will be removed at a regular interval of time and will not need any structural support. These are the types of nuts which are most commonly found having their application on the electrical panel covers, precision measuring tools, squares, as well as the service covers. The main advantage of using a knurled fastener is that it will help in improving the ease of removal, decreases the possibility of being over-tightened, which might not require any tools in order to manipulate the fastener.

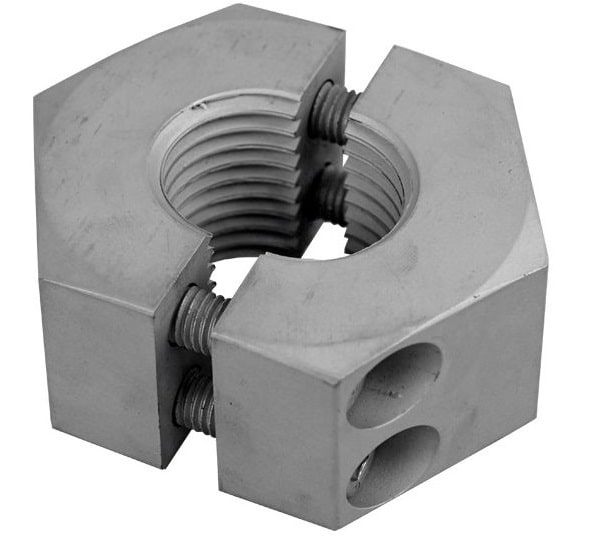

11. Split Nut: ( Types of Nuts )

A split nut is referred to as a nut that is named in such way as it is split lengthwise into two different pieces of the opposed halves so that the female portion of the thread can be opened as well as gets closed over the male thread of a bolt or the lead screw.

This feature is the one which allows the nut to move along the screw only when its open, without turning the screw or vice versa. Once the nut is closed it will resume the normal movement of a nut on a screw. This will include the axial rotation.

There is a split nut assembly which is commonly used for its positioning systems. For instance, the best example can be a lead screw of a lathe. This is one of the best machine element that will definitely make the single-point threading practical on manual as well as on the non CNC lathe machines. Usually the screw as well as the nut are also oiled for fulfilling the lubrication process. These are the types of provisions which are found prolonging the service life of the threads by minimizing the wear and tear.

12. Square Nut: ( Types of Nuts )

A square nut referred to as a nut which is designed in a very uncommon a nut pattern with four sides. In reference to its comparison with the standard hex nuts, these nuts are the ones which are found having a greater surface in contact with the part which is being fastened and thus provides a greater resistance in terms of loosening or the resistance of tightening. Unlike the other nuts these are the nuts which are less likely to become rounded-off once they get loose or tight cycles. Square nuts are one amongst the typically mated bolts along with the square-headed face. These nuts are found being used along with the flat washers in order to avoid the damage from the sharp edges.

HCL METAL

Our Locations

One-Stop Internationl Manufacturing Services